Showing 361 through 380 out of 418 articles containing "table saw jigs"

Tips & Techniques

…Woodsmith.com • 5 Handy Band Saw Sled When I get rolling on a project, my goal is to use each tool in the shop as efficiently as possible. My table saw will be set up … fitting into corners. 6 • Woodsmith / No. 230 Space-Saving Tool Platform My lathe and dovetail jig are tools that I don’t use every day. But I would never dream of giving either…Read More

Shop Notes

…Jig Creating 16 identical tapered and beveled roof panels for the martin house on page 26 presented an interesting challenge. The solution is to make a pair of taper sleds for the table saw. The starting point is tilting the saw blade and cutting a beveled edge on one side of each of …Read More

Bench Grinder Makeover

…-back adjustment knob is conveniently located in the bracket at the front of the jig. { An optional wide tool hold-down is designed to accommodate jointer knives up to 6" … opening. Notches in Deck. After making the long cuts at the table saw, finish the notches at the band saw. Mounting & Insert Holes. Drill the mounting holes and the hole for …Read More

Shop Notes

…sofa table (page 28) is a small piece of hardwood. It’s so small that I didn’t feel safe holding the piece by hand to make the taper cuts at the table saw. I … Then use a pattern bit to trim the edges of the slot flush. a. 1 NOTE: Use jig saw to remove waste between holes 2 !/2" pattern bit straightedge Raise workpiece above bench Hardboard …Read More

Shop Notes

… are made from 1"-thick hardwood 8!/2 6 2 1 !/2" brad point bit NOTE: Align jig to back of upright Clamp holds jig tightly to upright 6 1 Upright back REAR GUIDE 1 1 8 (/16" drill bit… small size, cutting these parts on a miter saw could be an unsafe operation. So it’s best to cut them at the table saw using a miter gauge with an auxiliary …Read More

Tips & Techniques

…where the nailer has misfired. 6 • Woodsmith / No. 237 { Slots in the back allow the jig to be moved up and down for working on different thickness of materials. … Jason Adler of Richland, WA, found himself searching for the power switch on his table saw, particularly when cutting large workpieces. To help quickly find the switch, he marks its…Read More

Shop Notes

…your table saw to cut the mitered end and then attach it to the box with screws. a. SIDE SECTION VIEW 45° 3!/2 #8 x 1!/4" Fh woodscrew BACK SIDE BASE BOTTOM SIDE 1#/4 7 NOTE: Jig … table saw. Start by using the pattern available at Woodsmith. com and attach it to both ends of the doors. I started with the right door. RIGHT DOOR. At the table saw…Read More

Tips & Techniques

… Kreg Jig & Clamp Base I recently built the Table Saw Storage Cart from Woodsmith No. 233. I decided to replace one of the pegboard frames with a plywood base for my Kreg Jig. By cutting… a. FRONT SECTION VIEW Tenon Jig Dowel QUICK TIPS Spare Change Spacers. Roger Page of Columbia, MO, was resawing stock on his band saw and noticed the kerf was…Read More

Butcher Block

…start, I sized the aprons to their overall dimensions, then installed my dado set in the table saw to make the tenons. TENONS. As you can see in Figure 1 below, the rounded … a pattern to mill the remaining three braces. With the jig and brace workpieces in hand, I headed over to the router table. The detail in Figure 2 shows how to set Materials, …Read More

Shop Notes

… MDF, cleat is #/4"-thick hardwood 6 %/8"-dia. 1&/8 1 2 NOTE: Double-sided tape holds jig in place while routing 3 a. #/8" Forstner bit !/2 !/4 !/4 FRONT SECTION VIEW …runner to fit your saw BASE 8%/16 FENCE 1!/4 1!/2 16#/4 Sandpaper keeps workpiece from slipping 11!/2 NOTE: Size runner to fit table saw slot #8 x 1!/2" Fh woodscrew Runner…Read More

Tips & Techniques

… back in the container they came in. The simple jig shown here solved both problems. A JIG FOR LOADING & STORAGE. The jig is built using a couple of small parts of …table saw. I also added a rare-earth magnet into the base. This gives me a place to set the nut from the table saw arbor. Now, everything is right at hand when I’m changing my saw…Read More

Tips & Techniques

…the blade angle and verified with a digital angle can be a pain, so I built this table saw gauge, tighten the lock bolts back sled. It allows me to leave my …by tightening the jam bolts. ADJUSTABLE PLATEN. The heart of Vacaville, California the miter jig is an adjustable platen that’s attached to a. a base with a continuNOTE: Runner is made #8 x 1" …Read More

Edge Sander

…need to be spot on. To get clean, accurate cuts, I made a simple jig that attaches to the table saw miter gauge (Figure 4, below). This holds each piece safely and securely … I first headed to the table saw to clip the corners on each one (Figure 3). To remove the rest of the waste, I used a clever jig at the router table (Figure 4, below). To find…Read More

Shop Notes

… are#/4"plywood #8 x 2" Fh woodscrew 16 1 16 STOCK STOP ROUTER STOP 4#/8 #/4 #/4 1!/8 16 NOTE: Jig is designed for a 4#/8"-dia. router base CLEAT Laminate 1!/8 2#/4 BASE #/4 Instructions for …spaced around the perimeter of the box. SIMPLE JIG. I turned to this easy-tobuild jig for use at the table saw. It goes together quickly and holds the…Read More

Tips & Techniques

…be the appropriate height to act as an outfeed support for my table saw. But, when I replaced my old table saw, the bench was suddenly too short to serve that purpose. …on the edge of some doors, I built the adjustable jig for the table saw that you see above. MITER GAUGE EXTENSION. The jig is a plywood miter gauge fence with a T-track recessed in…Read More

Coaster Set

…. Pivot pin is !/8"-dia. steel rod !/2"-rad. START WITH THE JIG It may sound strange, but instead of making parts, I began…through the center at the table saw. This allows you to easily remove the coaster blanks from the jig once you’ve routed … flush at the router table. SETTING UP TO ROUT. Now that you’ve got your jig and insert blanks in …Read More

Shavehorse

… cut the sides of the notch with a hand saw. Cut along the baseline with a coping saw and cleanup with a chisel and file. A jig saw would complete the whole job just as well (I…Mortises at the Table Saw. Rotate the miter gauge to create the splay in the mortise. Be sure to keep the beveled edge of the strip flat on the saw table (detail ‘a’). Make …Read More

Mortising Machine

…table adjusts vertically to locate the bit on the thickness of the workpiece. Another feature I like is the dust collection. It sounds a little lame, but many router-based machines and jigs …are used to register bushings that hold the guide rods. Cut the grooves at the table saw with the blade tilted 45°. This is shown in Figure 1 on the top of the…Read More

Kitchen Chair

…arc across the front edge. The first task is done at the table saw, the second at the band saw. SCOOPING THE SEAT. The shape that you choose to use … / No. 273 MAKING THE SIDES & BACKREST 1 Waste a. END VIEW E NOTE: Jig cradles Waste sides E Jig and rides along rip fence Jig 45° Tapering the Sides. The mirrored sides have a compound …Read More

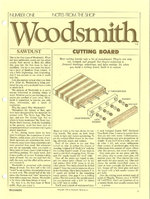

Tools & Techniques

… that requires a taper cut (like on the base of the Trestle Table shown in this issue). You don't have a taper jig, so ydu drop everything, run out to Sears to buy one… bar (as shown in the detail). Clean out this series of 5/16" holes with a coping saw and a file. Now slide a washer and a 14" x 3" machine bolt up through the bottom. Add some…Read More