Showing 21 through 40 out of 88 articles containing "table saw sled"

Crosscutting Tips

… with a table saw. Here are some of our favorites. Blade Alignment To get an accurate crosscut on the table saw, the blade has to be parallel with the saw’s …on the fence.) 1 a. a. 26 Woodsmith No. 112 Crosscut Sled To crosscut large panels on the table saw, I use a simple crosscut sled, see drawing at right. It features a hardwood fence …Read More

Saw Blade Rack

…PROJECT SAW BLADE RACK This simple rack will protect your blades and keep them close at hand. I ’ve seen quite a few woodworking shops where the table saw blades are hung on a… spacers.) And to cut the blank into spacers, I made a simple sled, see Figs. 1 and 1a. The base of the sled is a 4" x 12" scrap piece of plywood. By gluing a couple fences…Read More

Classic Picture Frames

… you. No, I didn’t use a router. Instead I used my table saw to hollow out the coves. By pushing the workpiece over the saw at an angle, you can create a wide variety of … previous one, however. Since the molding doesn’t sit flat, you’ll have to make a sled to hold it in position while 8 9 a. a. cutting the miters. This is shown in Fig. …Read More

Frame & Panel Storage Tables

… Turn to page 20 to find how to build and use this sled. 2 NOTE: Trim only two assemblies 3 NOTE: Roundovers routed on wide assemblies only 4…” as it’s glued together. So I used the top of my table saw as a perfectly flat assembly table. 5 F E E D FIRST: Glue up panel with moldings 6%/8” 3!/2” E F BOTTOM MOLDING E F BOTTOM PANEL (#/4” ply…Read More

Mitered Half Lap

… you’ll see, cutting this joint on the table saw isn’t difficult. But there is one thing to…sled rides along the rip fence and has a pair of fences to guide the workpieces across the blade. You can see how to cut a mitered half lap on the table saw…sled you see in the drawing at left. The sled is designed to ride along the rip fence of the table saw…Read More

Mitering Small Moldings

… moldings on the table saw doesn’t have to be a hassle. With a few tried-and-true techniques, a perfect fit is guaranteed. Cutting accurate miters on the table saw is always a …cut is complete, slide the workpiece away from the blade before retracting the sled. Woodsmith so positioning and control is easy and chipping is minimized. Plus, once…Read More

Craftsman Library Table

… illustrated in the drawing at the top of the page. It’s just a simple sled that used to both lay out the profile and rout it to shape.…16 !/4 Runners X V Z BB !/16 &/16 V Z &/8 U Y &/8 &/16 the plywood bottoms at the table saw, I took the sides to the router table to add the decorative profile. The profile is routed using a…Read More

Perfect Fitting Box Joints

…takes to make this super-strong joint is a simple shop-made jig, a dado blade, and a table saw. I often turn to box joints when I need an effective and attractive way to join the…the glue up and remove any glue squeezeout. (Remember to take the thickness of the sled into account when you’re setting the blade height.) There are a couple things to …Read More

Cutting Small Parts

…Small Parts The table saw is my tool of choice for cutting perfectly sized small parts. All it takes is the proper setup and the right technique. The table saw works great…the drawing above and the left photo below — a scaled-down cutoff sled attached to the miter gauge. The sled carries the nestled workpiece through the blade with a minimal effort …Read More

3 Ways to Make Tapers

techniques from our shop 3 tools for Cutting Tapers Table saw, band saw, or jointer — for making tapered cuts, all three tools have their place. Here are the … of elegance to the piece. TABLE SAW. When it comes to accurate tapers, it’s tough to beat the table saw. The only drawback is that it requires a jig, or sled, to carry the workpiece through…Read More

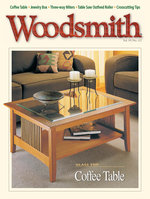

Coffee Table

… handful of stops that position each leg in the same place for consistent tapers. The sled runs against the rip fence. 52 • Woodsmith / No. 256 a. NOTE: Aprons and rails are #/4"-… to form the end shoulders, I find that a hand saw and a chisel work better than trying to do this at the table saw. The groove for the tabletop fasteners is easy to …Read More

Snow Sled

… while the top shoulder and tenon is angled at 7°. Cut the plumb tenon first. The table saw and c. #/4 a dado blade take care of this quickly. After that tenon’s cut, you can …the table saw if you must. Otherwise, a few swipes with a hand plane and you’ll be ready to glue the legs into the stretchers. RAILS. To add some rigidity to the sled and…Read More

Kid's Sled

…with trees or other immovable obstacles. For young children, this is a pull sled, not a coasting sled. The line between the use and abuse of anything isn't fine. It's obvious what's…to fit the mortises in the runners, see Fig. 7. I cut these notches on the table saw using the miter gauge for support. Since the fence is used as a stop, I fastened a…Read More

Sliding Cut-Off Table

… seen sliding tables (sometimes called sleds) like this before. What makes this one different? Well, it starts out like most cutoff tables — a plywood…saw, or Woodsmith No. 51. RUNNER AND BASE Since table saws vary in size, this cut-off table is designed so you can customize itto fityour saw's dimensions. RUNNER. Start building the cut-off table…Read More

Craftsman-Style Table Lamp

…I wanted more than just an angled guide. Instead, each post rests in a sled that carries the piece across the saw blade, as shown in Fig. 2. To hold the posts at an …. I did this by pressing the assembly down on a flat surface (the top of my table saw). LAMP COLUMN DOVETAIL JOINT forming a perfect 1/ "2 square opening in the center, as you can …Read More

Curved-Stretcher Accent Table

…a halflap joint in the middle of a curved workpiece would be troublesome on a table saw. So instead, I got out my hand saw and a few chisels to do the job. You can see the …the tapers, I put together a simple jig. It’s basically a plywood sled with some scrapwood fences added to capture the legs on the sled. I laid out the taper on one leg blank to …Read More

Router Table Box Joints

… CHOICE. Box joints can be made by any number of different techniques. The table saw with a dado blade is certainly one option for cutting the slots in workpieces … a fixed rear fence attached to a hardboard sled. The sled is sized to slide between the router table fence and a straightedge clamped to the table surface. The rear fence features slots…Read More

Router Table Box Joint Jig

… number of ways to create the machine-cut box joint slots — ranging from the table saw to the router table. For the majority of the box joints I make in my shop, I …runners are tightened via two knobs on top of the base. SACRIFICIAL FENCE. The sled also provides a place for mounting a sacrificial board along the front edge to control tearout…Read More

Sewing Table

…the subtle tapers that are on the inside faces of the legs. Over at the table saw, a simple sled with cleats supporting the leg will make the tapers uniform on the legs. … I planed these boards to thickness from 1⁄ " stock. Then made the rab2 beted edges at the table saw. Pin nailing the back in place completed this stage of building. Now you can …Read More