Showing 41 through 60 out of 177 articles containing "dowel making"

Tips & Techniques

… showed a method of marking the center point on the end of long dowels that works well. For 'short dowels, I use a slightly different method that not only finds center, but … Johnson Des Moines, Iowa SCRAP WOOD CORNER CLAMPS Not too long ago, I had to make a large number of Lazy Susan shelves. Everything went together just fine until I realized I …Read More

Talking Shop

… issue. I needed small splines for the tray, small square stock to make the dowels, and thin wedges to hold the dowels in place. If the saw is set up so small strips like… Toy method — just cut a kerf in the end of the dowel and add a wedge. To make sure the kerf is centered on the dowel, I used a small holding jig, see Fig. 4. Start by cutting…Read More

Shop Notes

…the fence. TEST CUT. Now you're ready to make the first test cut on a dowel. Turn on the router and slowly push the dowel down into the hole turning it in a … correctly, you can make the same size tenons all day. (It's almost as much fun as sharpening pencils.) FITTING TENONS/DOWELS IN HOLES Sometimes round tenons or dowels are just a little …Read More

Tips & Techniques

… can easily be chiseled off. John A. Ibumsend CoUhoater, Michigan CONDUIT BAR CLAMP Most woodworkers make do with fewer bar or pipe clamps than would be ideal for a project simply… area. To strengthen up the joint (and all of the comers) I added two %" dowels. The dowels can be added down from the top for a decorative appearance, or up from the …Read More

Tips & Techniques

…ms been set. Also, check to make sure that your framing square is truly square. RIGHT LENGTH ON SHORT DOWELS I use quite a few short dowels for gluing joints together. And … mined the dowel but became a safety hazard as well. I resolved these problems by making a very simple jig from 2x4 stock that can cut four different sized dowel diameters on…Read More

Tips & Techniques

…Dowel Centers Dowel centers are useful for marking matching dowel holes in adjoining pieces — if they don't fall out before making their mark. To prevent this, place a piece of masking tape across the dowel centers. The points will still go through the tape and make…Read More

Oval Box

…1 V \ Wl 3 HJ2 MIRROR f / / ON / [J TRACING 1/ PAPER JJ / 1 TRACE ^; AROUND >^ PERIMETER----- OF MIRROR 1T0 make a template for an oval mirror, lay the mirror on … a recess for the mirror, see Fig. 5. Tap index dowels P/W'-dia.) into the holes, but don't glue them in.…Read More

Armoire

…AND ROD W Shelves (7) 3/4 ply x 181/6-221/2 X Shelf Edging (7) 3/4X1- 22Vfe Y Clothes Rod (1) 1" dowel x 22 V* Z Rod Supports (2) 3/4X2-19 DOORS AA Inside Stiles (2) 3/4x3-68'/* BB Outside…1 "-dia. dowel to length so it wedges between the supports. No. 67 Woodsmith 23 DOOR FRAMES The last step in building the armoire is to make …Read More

Accent Lamp

… length of V2" dowel in each end…dowel in the end of the post, all you have to do is rotate the post between cuts. So after making the first cut, rotate the post 90* and make another cut. (Note: Do not rotate the jig between cuts. Always keep the edge of thejig that's farthest away from the dowel…Read More

Shop Stool

… 24.) To make sure this stool holds up as long as the old metal ones, we used solid oak throughout. (For sources of oak dowels, see page… stretcher holes. LEG(i (1 V4" DOWEL) W ROUND-OVER ON BOTTOM END -26V2" LOWER STRETCHER (W DOWEL) (0 Cj) UPPER STRETCHER t'/e" DOWEL) CENTER KERF CI. ON DOWEL Note: For appearance, I rotated the …Read More

Tips & Techniques

…throwing away the old blades, 1 found a new use for them—they make great cabinet scrapers, see photo. To make a scraper, first remove the blade from the handle and grind off… than starting to glue up a project only to discover that your dowel holes aren't deep enough — the dowels are bottoming out before the joint is closed. To avoid this problem,…Read More

Drafting Cabinet

…. NOTE: ALIGN PIVOT BLOCK TO EDGES OF DOOR FRAME CROSS SECTION — 2W--------wi 3/s" DOWEL PLUG S' J^ pv DOOR STILE W X 2V4" STEEL ROD W SPACER TAP PIVOT ROD THROUGH PIVOT…a bulletin board into the back of the cabinet, see Fig. 1. bulletin BOARD. You can make your own bulletin board by fastening a piece of acoustic ceiling tile to the…Read More

Tips & Techniques

…to finished length (IV2'1). Now drill a hole, centered in the groove, for a piece of 3/4"-dia. dowel that serves as a shoe, see Fig. la. The shoe prevents the thumb screw from … (as on a jig), I use a strip of W-wide plastic labeling tape. The tape, used for making embossed labels, is adhesive-backed, so it's easy to attach to the sliding surfaces …Read More

Slant Front Desk

…page 26 we're showing how to build the ogee bracket feet. molding strip. After making and installing the feet, cut a blank for the molding (L) to Dnished width and rough …Fig. 19. This allows the support to slide with a minimum amount of binding. DOWEL PIN & BRASS KNOB. Now glue a dowel pin into each door support as a stop, see Fig. 20. Then a …Read More

Fire Truck

…from each one. Then, to make sure the legs are oriented correctly, mark the top face of each leg with an "X". BACKING BOARD - -DIA. DOWELS 1" LONG ^ f% On one leg, mark…HEADLIGHT ► To bend the brass rods for the rails, build a form using Vjf dowels. The front dowels should be 2Vgn apart. Also, drill out a depression for the lights. LIGHTS & …Read More

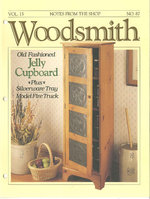

Jelly Cupboard

… 84" (TWO BOARDS S 7 Bd. Ft. Each) G v// L L G c SUPPLIES • (3) Hinges - 2" x T/16* • 3/8* Birch Dowel -12" • V4" Birch Dowel-18' • (1) 1V4" Maple Knob • (24)#8xl'/2" Fh woodscrews • (6) #8x13/," Fh woodscrews… to Shop Notes on page 16 for information on making these keeper strips. Q. CROSS SECTION KEEPER -STRIP ®…Read More

Clamping Tips

… during clamping — free- ing your hands and preventing the clamps from racking the corner. To make this corner support, cut two dadoes 90° to each other, using the miter gauge set… arm and drill two holes in the stationary arm. To keep the gauge aligned, glue a dowel into the hole closest to the end of the stationary arm. Then connect the arms…Read More